SENSOR MOUNTS

Swivellink

is the highly adaptable mounting hardware that will simply

and securely mount precision equipment in industrial

environments including robot end-effectors.

Whether you need an emergency stop button, operation

indicator lighting or an interface monitor to be raised for

optimum ergonomic utility, or you have a vision system that

would work best if it could be mounted further out over your

conveyor line, Swivellink has the hardware that will hold

your equipment precisely in place, wherever you want it to

be.

Choices include using a single- or duel-arm to mount either

cameras or lights. Swivellink has mounting kits that fit

equipment from all major industrial vision system

manufacturers, each available in hundreds of

configurations.

Positioning of operation indicating lights for maximum

visibility has never been easier. The mounting kit for any

monitor with the industry standard VESE mount platform makes

placing your factory floor monitors in their optimum position

a snap.

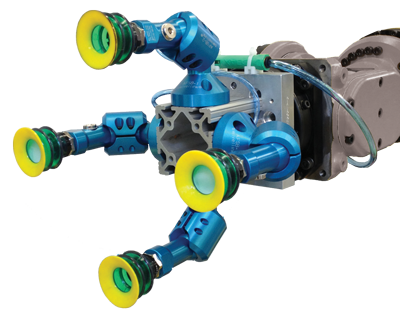

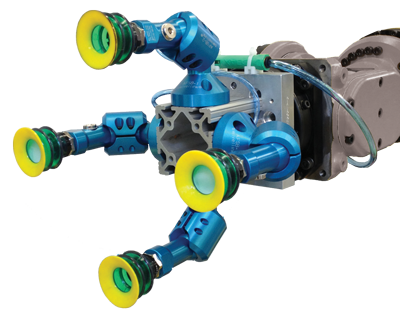

EOAT

Any

robot’s functionality in your factory will be

determined by its ability to pick up the parts you need to

modify, mount, or manufacture. Using vacuum to lift has never

been easier than with Swivellink’s ball, socket and

knuckle system. Just place your robot in a normal, known,

pick-position, adjust the EOAT to fit the part you need to

move, place the vacuum cups where you want to grip, and

tighten the knuckles to lock the cups in position.

Swivellink solutions like this work with centralized and

decentralized vacuum solutions.

VISION CAMERA MOUNTS

Swivellink’s

standard product series allows you to select solutions to

your common mounting needs. The ball and socket design allows

for 3-dimensional positioning and mounting. Knuckles provide

an extreme range of motion while maintaining the internal

through feed capability without pinching a cable. Four

socket head cap screws securely lock the position. It really

is that simple; just combine bases, knuckles, and links to

fit your exacting requirement.

Swivellink even has a heavy duty product that uses the same

ball and socket design, but for heavier requirements such as

computer monitors. The knurled ball base and ball links give

you more stability and grip to support your equipment. For

the heavy duty series, the knuckle includes a clamp handle

which helps when making quick adjustments

HTE is your Swivellink mounting system selection, sales and

implementation resource if you are located in

Kansas,

Missouri, and Illinois.

Swivellink

is the highly adaptable mounting hardware that will simply

and securely mount precision equipment in industrial

environments including robot end-effectors.

Swivellink

is the highly adaptable mounting hardware that will simply

and securely mount precision equipment in industrial

environments including robot end-effectors. Any

robot’s functionality in your factory will be

determined by its ability to pick up the parts you need to

modify, mount, or manufacture. Using vacuum to lift has never

been easier than with Swivellink’s ball, socket and

knuckle system. Just place your robot in a normal, known,

pick-position, adjust the EOAT to fit the part you need to

move, place the vacuum cups where you want to grip, and

tighten the knuckles to lock the cups in position.

Swivellink solutions like this work with centralized and

decentralized vacuum solutions.

Any

robot’s functionality in your factory will be

determined by its ability to pick up the parts you need to

modify, mount, or manufacture. Using vacuum to lift has never

been easier than with Swivellink’s ball, socket and

knuckle system. Just place your robot in a normal, known,

pick-position, adjust the EOAT to fit the part you need to

move, place the vacuum cups where you want to grip, and

tighten the knuckles to lock the cups in position.

Swivellink solutions like this work with centralized and

decentralized vacuum solutions. Swivellink’s

standard product series allows you to select solutions to

your common mounting needs. The ball and socket design allows

for 3-dimensional positioning and mounting. Knuckles provide

an extreme range of motion while maintaining the internal

through feed capability without pinching a cable. Four

socket head cap screws securely lock the position. It really

is that simple; just combine bases, knuckles, and links to

fit your exacting requirement.

Swivellink’s

standard product series allows you to select solutions to

your common mounting needs. The ball and socket design allows

for 3-dimensional positioning and mounting. Knuckles provide

an extreme range of motion while maintaining the internal

through feed capability without pinching a cable. Four

socket head cap screws securely lock the position. It really

is that simple; just combine bases, knuckles, and links to

fit your exacting requirement.